As an example under iso13006 the tolerances are.

Ceramic tile tolerances.

Accordingly the tolerance for variation from tile to tile includes the actual warpage of the tile.

Tolerances when tiles 8 x 8 or larger had been selected.

The intent of the standard is to define reasonable lippage from one tile to another.

2a take one tile and place it face up in a table or counter.

This document con tains both a definition and specific dimensional tolerances for rectified tile.

2 the tiles themselves may not be as flat as one would ordinarily think.

The size requirements for rectified tile tile q a by bill griese rectifying the misconceptions associated with rectified tile and.

However as of 2011 subsurface tolerances for tile installation based on tile unit size have been updated in the tcna handbook.

Up to 10 of tiles as supplied.

When a tile is warped but within standards all of the corners cannot be set in the plane of the adjoining tiles.

There are ways to measure.

2c can you see daylight between the two tiles.

Table 1 in as 4459 1 1999 also iso 10545 1 1995 ceramic tiles part 1.

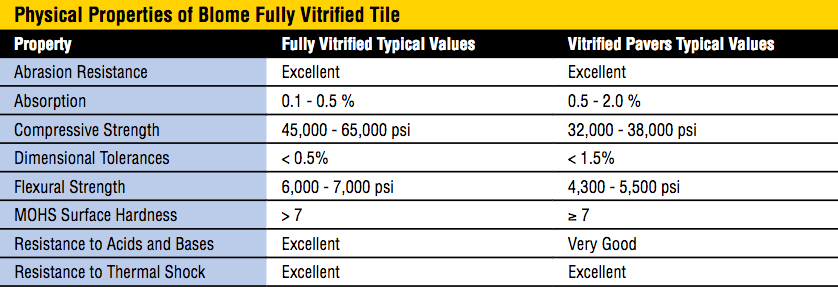

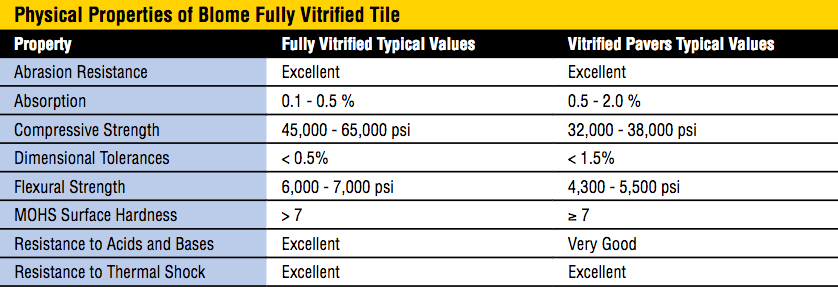

Both specifications use the water absorption characteristic to define product type as water absorption is a commonly related item for all.

2 how many tiles from any one batch can be outside the tolerances described in iso 13006 1998.

There are rectified porcelain tiles that are more consistent in size tolerances where they recommend 1 16 inch wide grout joints.

For tiles with all edges less than 15 the maximum allowable variation is 1 4 in 10 and no more than 1 16 in 12.

Many times larger tiles are warped curved pillowed or just plain crooked.

Standard specification for ceramic tile that is currently being balloted rectified tiles are addressed.

Maximum deviation from square edge is 0 5 of length of tile.

Sampling and basis for acceptance allows one tile in 10 to be outside the above dimensional tolerances i e.

2b place another tile face down directly over the first.

Tile lippage which is were one edge of a tile is higher or lower than the adjacent tile edge is normal to a degree but there are limitations.

Manufacturing tolerances for ceramic tiles.

Ceramic tiles are generally manufactured to conform to the european agreed standard of which the english language version is bs 6431 or the newer iso dis 10545.

Bowing or curvature is one of the most common imperfections however bowed tiles are deemed acceptable if they are within specified tolerances.

The ansi a108 02 standards say that acceptable lippage for floor tiles with a grout joint width of 1 16 to less than 1 4 is 1 32 plus the allowable inherent warpage of the tile.